Another requirement for the car to gain its MOT (roadworthiness test) was to reinstate windscreen washers. The reservoir had long disappeared, with some of its wiring and plumbing. And the windscreen washer jet was missing, well, its jet!

Starting with the washer jet, I found the item was common to the Daimler Dart and earlier Cobras. It was probably used on a number of other plastic cars of the era as it had the merit of being held to the bodywork by two screws. The good news was knowing its source; the bad news was finding that these are entirely unobtainable.

Fortunately, I found a substitute (designated for the Dart) from David Manners. This consisted of a small, machined pedestal that presented an 8mm hole into which a conventional twin-jet washer could be bolted. Expedient and reassuringly expensive.

Starting with the washer jet, I found the item was common to the Daimler Dart and earlier Cobras. It was probably used on a number of other plastic cars of the era as it had the merit of being held to the bodywork by two screws. The good news was knowing its source; the bad news was finding that these are entirely unobtainable.

Fortunately, I found a substitute (designated for the Dart) from David Manners. This consisted of a small, machined pedestal that presented an 8mm hole into which a conventional twin-jet washer could be bolted. Expedient and reassuringly expensive.

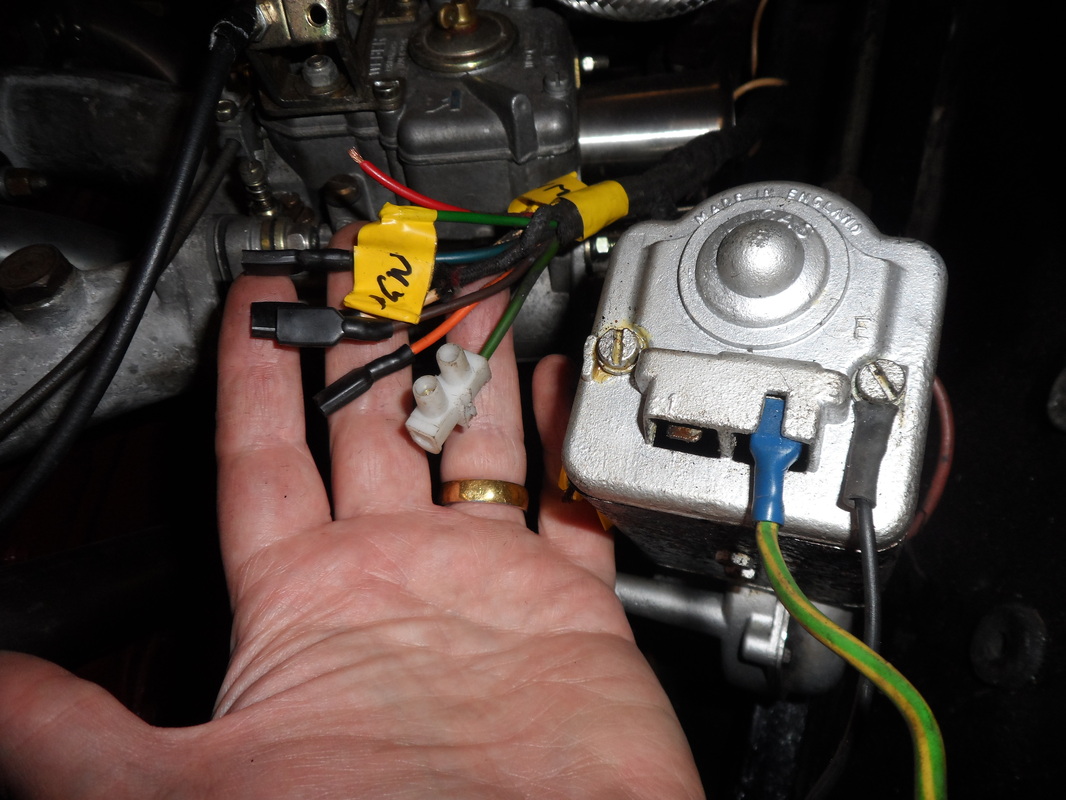

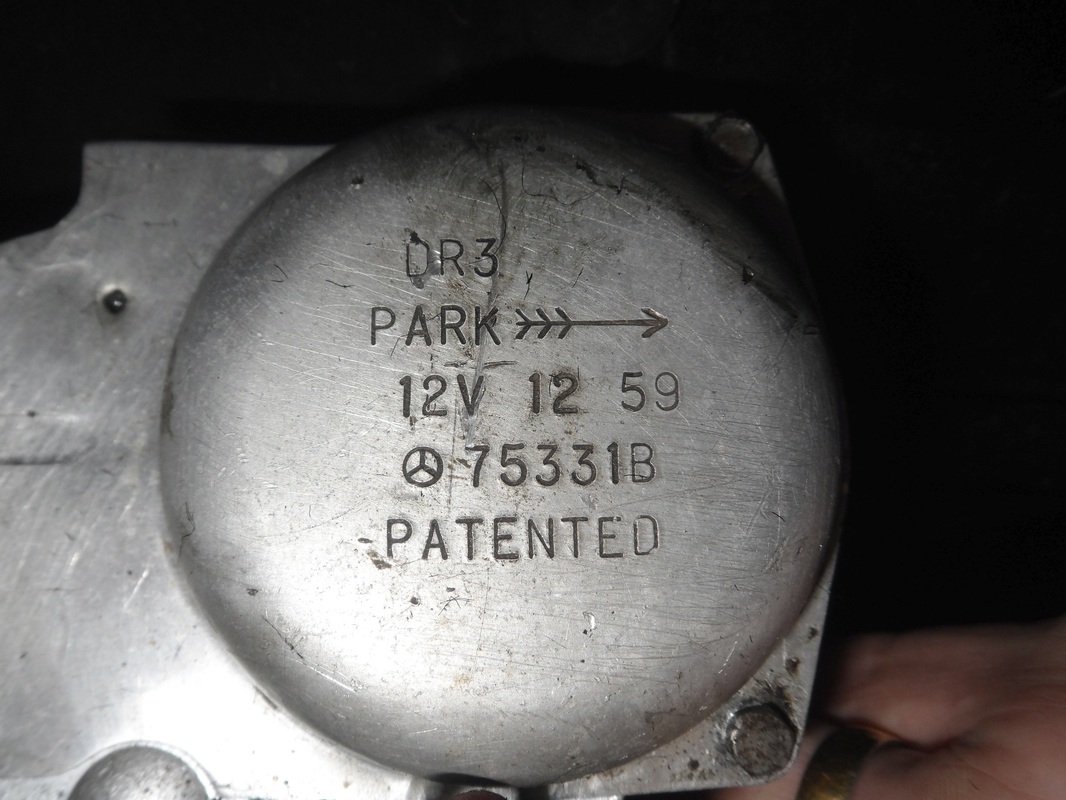

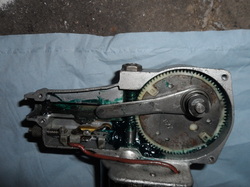

The reservoir and pump should be a Lucas 2SJ, another electro-mechanical wonder of its age that delivered a measured volume of water for each 'hit' of the momentary dashboard switch. I shall save that story for another day, when I have one that is adequately restored. But, in the meanwhile, my son and I reinstated the cable runs from where they had been terminated adjacent to the wiper motor. And we fixed a cheap eBay reservoir and pump in the correct location for the 2SJ that will eventually follow.

RSS Feed

RSS Feed